Background

Instructions

Data Storage

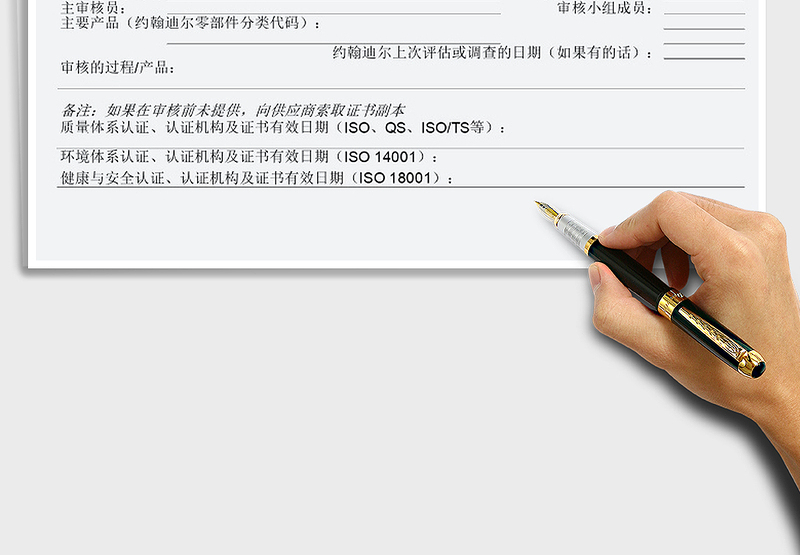

This on-site audit is intended for parts with a high level of criticality to determine the effectiveness and conformance of process controls when performing work for John Deere. The work performed can include manufacturing operations at a John Deere or supplier' facility, or operations sub-contracted (sub-tier). This audit may also be performed on similar parts when the work has not yet been sourced, or when preparing for full production. It is intended to be conducted by John Deere personnel familiar with the requirements of the JDS-G223 Supplier Quality Manual, the requirements of the selected parts, and processes used in manufacturing the selected parts.

This audit is not intended to cover the supplier's or John Deere's entire quality system. To conduct a thorough review of the supplier's quality system, an audit must be conducted an using the JDS-G223 Supplier Quality System Audit Questionnaire and led by a qualified Lead Auditor. A review of John Deere's quality system is conducted with internal audits by trained auditors or consultants.

The lead auditor and team members must be qualified to conduct a Process Verification Audit.

Prior to the on-site audit, review the most recent part specifications (drawing) and Control Plan on file for relevance, design level, and date. Also, review any other pertinent data or documents, such as key characteristics, Gage R&R studies, capability study information, Materials Engineering report / material certification, inspection data, FMEAs, internal and external failure data, and/or the supplier's internal procedures.

Schedule the on-site audit with the part manufacturer at a time when the identified parts are being produced with the processes to be audit......

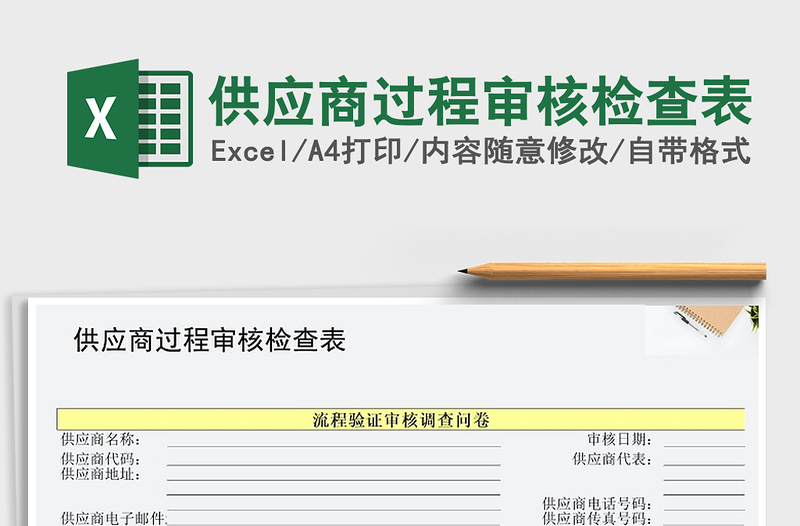

表格大全网提供2025年供应商过程审核检查表模板供会员下载,作品格式为xlsx。更多精彩其他表格素材,尽在表格大全网。

标签:供应商过程审核检查表